High Bay Lighting FAQ's

What are High Bay Lights?

Generally, any light that hangs 20’ or higher from the ground can be considered a high bay light. The name “high bay” is used because of the traditional use of these lights in industrial or commercial bays. High bay fixtures are often attached to ceilings by chains, hooks, or pendants. They can also be attached directly to the ceiling. What lighting types are available for high bay lights?

- LED

- Induction

- Metal Halide

- Fluorescent

What fixture types are available for high bay lights?

UFO High Bay Lights

- Round/circular in shape

- Create a spotlight effect with a circular beam of light (hence the UFO reference)

- Easier to control light direction

- Best above 13’ install height

Linear High Bay Lights

- Rectangular in shape

- Wider angle of light beam

- Often good for hallways, aisles, corridors

Wet Location High Bay Lights

- Look like other high bay lights, but are sealed to protect internal components from moisture

- Designed to withstand harsh indoor and outdoor conditions

Where are high bay lights used?

- Industrial and Manufacturing Facilities

- Assembly Lines

- Workshops

- Warehouses

- Large Retail Stores

- Recreational facilities, gyms

- Event Centers

- Aircraft hangars

- Garages

- Barns

- Subway/Transit

- Parking Garages

What to look for when buying High Bay Lights

Light Temperature

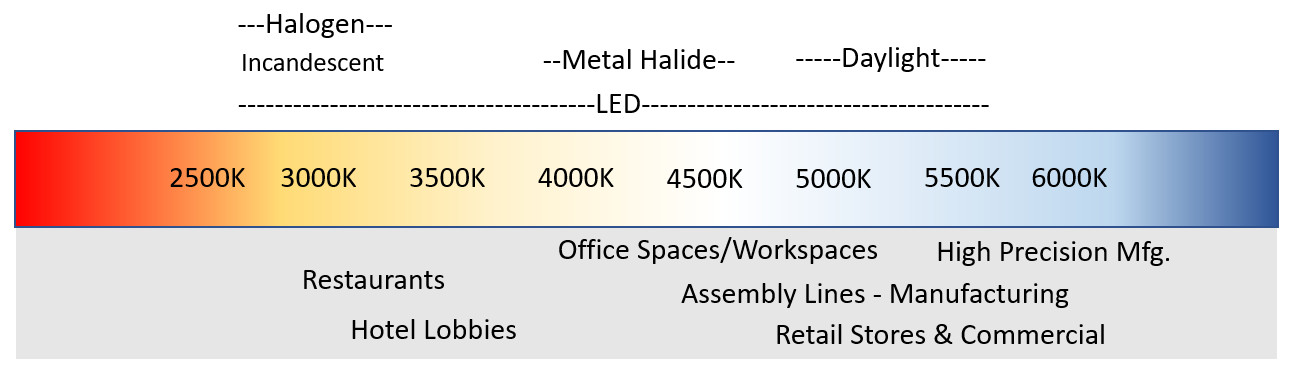

Light Color is measured in units called Kelvins. A lower number in Kelvin means the light is warmer and more toward the red scale. This can be good for restaurants and home settings. A higher number in Kelvin, on the other hand, means the light is cooler and more on the blue scale. Cooler lights are more suitable to retail, industrial and commercial applications. 4000 Kelvin and higher can increase productivity and decrease eyestrain, as it more closely mimics daylight. If you are purchasing LED high bay lights, there is a range of options that is larger than other types of lighting.

Efficacy or Lumens Per Watt

Efficacy is a measurement of how efficiently a bulb converts energy into visible light. It is measured in Lumens per Watt. A higher lumen per watt ratio can reduce the number of watts needed to light a space, and result in significant energy savings. Lower efficacy lights are generally less expensive to buy, which makes them attractive. However, over the lifetime of the light, a higher efficacy light will save more than enough energy to offset the higher initial cost and add lifetime savings. Additionally, higher efficacy lights can save on initial cost by providing more visible light from fewer bulbs. For example, a fluorescent high bay light with efficacy of 75 lumens/watt will provide only half the visible light compared to an LED with 150 lumens/watt. You would need twice the number of fluorescent lights as LED’s, which doubles initial cost.

| Light Type | Average Lumens per Watt |

| Fluorescent | Up to 75 |

| Induction | Up to 90 |

| Metal Halide | Up to 100 |

| LED | Up to 190 |

Foot Candles

Foot candles (fc) are a US measurement used to calculate lighting levels. A foot candle is the illumination of one lumen per square foot of area, with an even distribution. (SI units are measured in lux, or one lumen per square meter.) The number of foot candles needed depends on the type of use of the space being lit. The brighter the space needs to be, the higher number of foot candles are required.

| Use | Foot Candles |

| Parking Garage | 10 fc |

| Warehouses | 30 fc |

| Office Spaces | 50 fc |

| Assembly and Factory | 70 fc |

| Retail Spaces | 80 fc |

| Visually Intensive Work | 100 fc |

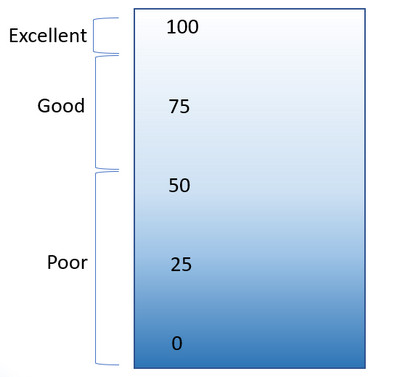

Color Rendering Index (CRI)

CRI measures the ability of a light source to accurately render colors compared to natural lighting. A higher CRI, the closer the colors will appear to how they appear in natural sunlight. For any applications where color is important, like clothing retail or commercial printing, you will want to look for bulbs with a higher CRI.

Lifespan

Different types of lighting can have different lifespans. As we saw with efficacy, lifespans of bulbs impact both initial purchase cost and costs over time. Less expensive lights, like fluorescent lights, have a shorter lifespan, while LED’s have a much longer lifespan which results in longer replacement times and significant cost savings.

| Type of Light | Average Lifespan |

| Metal Halide | 6000-15,000 hours |

| Fluorescent | 24,000-36,000 hours |

| Induction | 80,000-100,000 hours |

| LED | Up to 200,000 hours |

Number of Lights Needed

The size, shape, and use of the space you are lighting will dictate how many lights will be needed. Additionally, as explained above, the efficacy, CRI, cross lighting, and foot candles of the lights themselves, calculating the number of lights needed can be a complex task. Many turn to lighting consultants to help them determine their exact lighting needs. Some manufacturers provide calculators that will assist with determining the number of lights needed using their specific products in your space. Below are some things to take into consideration as you calculate how many lights you need.

Light Height

The height at which you install high bay lights also impacts the number of lights you will need for your space. As your ceiling height or install height increases, you will need more lumens to adequately light their space.

| Ceiling/Install Height | Generally Recommended Lumens |

| "<"11 feet | 10,000-12,000 |

| 10-19 feet | 12,000-21,000 |

| 20-29 feet | 22,000-35,000 |

| 30-39 feet | 35,000-41,000 |

| 340+ feet | 47,000+ |

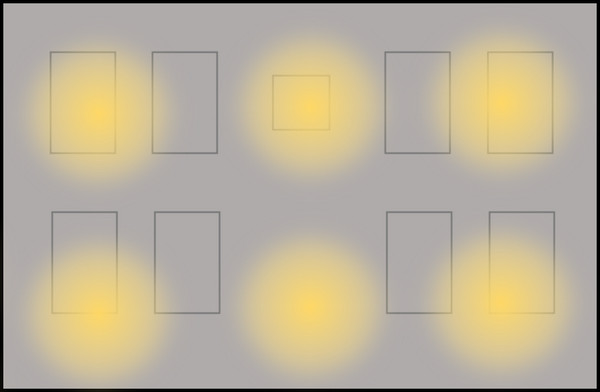

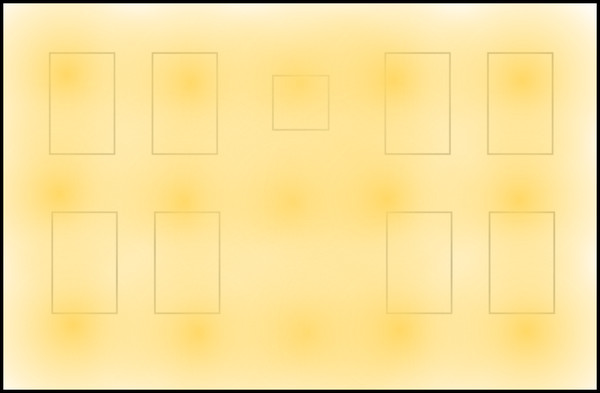

Light Spacing

How far apart lights are placed has a big impact on the number of lights you will need. A general listing of light spacing is below, but how the space is used will also factor into how closely you space your lights.

Lights will need to be spaced in a way that eliminates dark areas and creates a more uniform lighting throughout the space.

| Ceiling/Install Height | Generally Recommended Spacing |

| 10 feet | 12-15 feet apart |

| 20 feet | 15-19 feet apart |

| 30 feet | 19-29 feet apart |

| 40 feet | 30-40 feet apart |

Improperly spaced lighting leaves inadequately lit areas over certain workspaces in the below floor plan.

Shadow areas eliminated by using proper light spacing in the below floor plan.

Cross Over Lighting

Cross Over Lighting refers to light coming from multiple directions, which helps to eliminate shadows and give a more even light distribution. Light from at least 3 directions is recommended to avoid light “hot spots” and give an even lighting appearance.

| Shadow from Single Lighting Source | Shadow Mitigated with Crossover Lighting |

|

|

Light Pattern

The pattern of how the light hits the ground is important when determining which type of high bay lights to purchase. UFO high bays have a circular lighting pattern that is more controllable, while linear high bays have a wider beam angle, that lights more evenly.

| Linear High Bay Light Pattern | UFO High Bay Light Pattern |

|

|

How to increase energy efficiency with High Bay Lighting

Use LED’s - LED bulbs use far less energy and produce more light than other types of bulbs, which can lead to significant cost savings, especially when lighting thousands of square feet in a factory or retail location. Use Lighting Automation – At a minimum, you will want to use timers for adjusting when high bay lights are on or when to dim them. For example, a retail store may have lights dim at closing time, then turn off 1 hour later to give workers a window in which to depart after closing. Additionally, you can use motion sensors to control high bay lighting, which allows the lights to shut off after a period of inactivity, which can give even greater energy savings. This is especially useful for areas that do not have consistent traffic throughout the day.

Can you retrofit LED Bulbs into existing high bay fixtures?

Retrofit LED bulbs are available and are a great option for those who do not want to replace all their lighting fixtures. This can provide you with the cost savings of an LED lamp, without the expense of updating fixtures. Retrofit LED lamps are available for many types of lights, including high bays.

Other advantages of using LED for high bay lighting

- Higher lumens per watt

- Cooler running temperature

- No UV emitted

- No mercury used

- Less glare

- Little to no ‘warm up’ time

- Multiple light temperatures from warm to cool for different needs